Effective Strategies for Supply Chain Risk Mitigation: A Comprehensive Guide

Understanding Supply Chain Risk Mitigation: Importance and Key Concepts

What is Supply Chain Risk Mitigation?

Supply chain risk mitigation refers to the strategies and processes that organizations implement to identify, assess, and reduce potential risks within their supply chains. It involves proactively preparing for disruptions or challenges that could impact the efficiency, costs, or overall functioning of the supply chain.

Risks in supply chains are inevitable due to a variety of factors, such as supplier failures, transportation delays, fluctuating costs, or geopolitical events. Therefore, mitigating these risks ensures that businesses can continue operations without significant interruptions.

Types of Risks in the Supply Chain

Businesses face various types of risks in their supply chains, each of which can affect different areas of the organization. These risks include:

- Operational Risks: Disruptions in day-to-day operations due to supplier issues, equipment failures, or natural disasters.

- Financial Risks: Volatility in prices, currency fluctuations, or changes in market conditions that may impact the cost of goods and services.

- Strategic Risks: Shifts in customer demand, changes in industry trends, or the emergence of new competitors that affect the company’s long-term supply chain decisions.

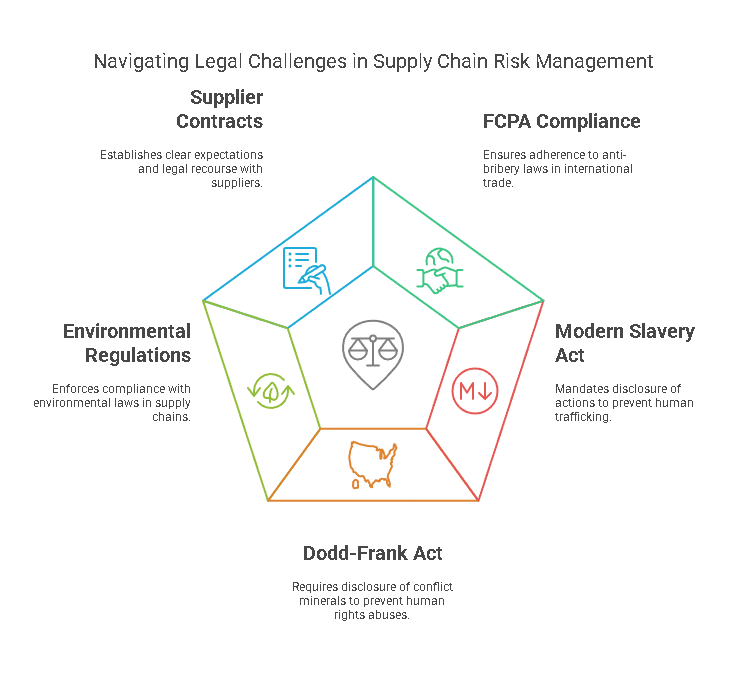

- Compliance Risks: Regulatory changes or violations related to environmental, labor, or trade laws that can lead to fines or legal consequences.

Why is Supply Chain Risk Mitigation Important?

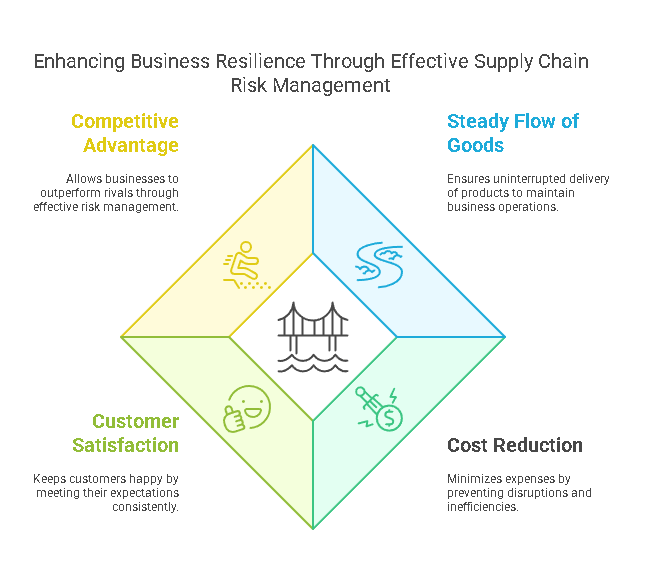

Supply chain risk mitigation is crucial for maintaining a steady flow of goods and services, reducing the likelihood of costly disruptions, and ensuring customer satisfaction. Businesses that fail to address potential risks in their supply chains may experience significant operational setbacks, financial losses, and damaged reputations.

For example, during the COVID-19 pandemic, businesses that lacked contingency plans for supply chain disruptions were forced to halt production or delay shipments. This highlighted the vulnerability of many supply chains and underscored the importance of having proactive risk management strategies in place.

Additionally, mitigating risks can help businesses maintain competitive advantages. Companies that effectively manage supply chain risks are more likely to deliver products on time, reduce costs, and meet customer expectations consistently.

Common Supply Chain Risks

Here are some of the most common risks that businesses encounter in their supply chains:

- Supply Shortages

Shortages of raw materials, parts, or finished goods can disrupt production and delay customer deliveries. For instance, a shortage of microchips in the automotive industry caused significant delays in car manufacturing globally. - Transportation Delays

Logistics issues, such as traffic disruptions, port congestion, or weather events, can cause delays in shipping products to customers or receiving raw materials from suppliers. For example, the Suez Canal blockage in 2021 disrupted global trade for several days. - Supplier Bankruptcy

If a key supplier goes out of business or faces financial difficulties, it can create a domino effect throughout the supply chain. This risk can be particularly impactful for businesses that rely on a single supplier for critical components. - Cybersecurity Threats

As companies increasingly rely on digital technologies to manage their supply chains, they become more vulnerable to cyber-attacks. A data breach can lead to the loss of sensitive information, financial losses, and damage to the company’s reputation. - Geopolitical Risks

Political instability, trade wars, tariffs, and sanctions can all affect the smooth flow of goods across borders. For example, the trade war between the U.S. and China led to tariffs on many products, raising costs for businesses and consumers. - Natural Disasters

Events like hurricanes, earthquakes, and floods can disrupt transportation routes, destroy inventory, and damage infrastructure. Businesses in regions prone to natural disasters must be prepared with contingency plans to mitigate these risks.

Effective Strategies for Mitigating Supply Chain Risks

Risk Identification and Assessment

The first step in mitigating supply chain risks is identifying potential threats to the supply chain. Without a clear understanding of what risks exist, businesses are unable to effectively plan for or address disruptions. Here are several approaches businesses can take to identify risks within their supply chains:

- Risk Mapping: Risk mapping is a process that visually plots potential risks and their impact on the supply chain. By visually understanding the risks, businesses can evaluate the severity and likelihood of each potential issue.

- SWOT Analysis: A SWOT (Strengths, Weaknesses, Opportunities, Threats) analysis helps businesses evaluate internal and external factors that might expose their supply chain to risks. By focusing on weaknesses and external threats, companies can address key areas that may be vulnerable.

- Scenario Planning: Scenario planning involves creating multiple “what-if” scenarios to predict the potential impacts of various risks. For example, a company might simulate natural disasters, trade disputes, or a supplier’s financial collapse to see how it would affect its supply chain.

Regularly assessing and updating risk assessments is critical. As businesses evolve, so do the risks they face. An annual or semi-annual review ensures that companies remain proactive about any emerging threats.

Diversification and Supplier Management

A key risk mitigation strategy is supplier diversification. Businesses that rely on a single supplier for essential materials are vulnerable to supply disruptions. If that supplier faces operational issues, natural disasters, or financial problems, it can bring the entire supply chain to a halt.

- Supplier Diversification: By sourcing from multiple suppliers in different locations, companies can reduce the risk of being severely impacted by one supplier’s failure. Diversification helps spread the risk, so if one supplier faces challenges, other suppliers can step in.

- Regional Sourcing: To avoid risks associated with geopolitical instability or natural disasters in a particular region, companies can source materials from multiple regions. This ensures that if one area faces disruptions, businesses can still maintain the flow of goods and services.

- Supplier Relationships and Contract Management: Cultivating strong relationships with suppliers is essential. These relationships foster better communication, quicker issue resolution, and shared responsibility for managing risks. Additionally, contracts should include clear terms for managing risks, addressing delays, and creating contingency plans to protect both parties.

Technology and Data Analytics for Risk Mitigation

In the modern supply chain, technology plays a crucial role in identifying, monitoring, and mitigating risks. Businesses that utilize advanced tools can gain real-time insights into their supply chains and act quickly when risks arise.

- Predictive Analytics: Predictive analytics helps businesses forecast potential risks by analyzing historical data. Machine learning algorithms and AI can predict delays, supply shortages, and demand fluctuations, allowing businesses to make proactive decisions.

- Real-Time Monitoring: Technologies like RFID tags, GPS tracking, and IoT sensors allow companies to monitor their supply chains in real-time. This technology provides visibility into inventory levels, shipment statuses, and equipment conditions, enabling companies to address problems as soon as they arise.

- Blockchain for Transparency: Blockchain offers secure and transparent record-keeping, which enhances the traceability of goods in the supply chain. This technology provides tamper-proof records, reducing risks associated with counterfeit goods, fraud, or ethical violations.

- Artificial Intelligence (AI): AI can help businesses detect anomalies within the supply chain. By analyzing vast amounts of data, AI can identify potential risks and offer solutions in real time. For instance, AI can flag potential delays in the supply chain based on irregular patterns.

Building Strong Partnerships and Communication

Collaboration is critical when managing supply chain risks. Strong communication and partnerships with suppliers, logistics providers, and other stakeholders help businesses quickly address and resolve issues.

- Communication Protocols: Businesses should establish clear communication protocols to ensure information flows efficiently between all parties. Having systems in place for frequent updates and emergency responses can help mitigate risks before they escalate.

- Partnerships for Risk Management: Partnering with trusted third-party risk management providers offers additional expertise and resources. These third parties can conduct risk assessments, provide supply chain insights, and even assist in handling disruptions.

Services by Precisehire

In addition to the strategies mentioned above, companies can also benefit from leveraging professional services, such as those offered by Precisehire. Precisehire offers comprehensive services for businesses looking to mitigate risks in their supply chains, including background checks for suppliers, contractors, and other business partners.

- Supplier Screening: Precisehire helps businesses verify the reliability and integrity of their suppliers by conducting thorough background checks. These checks include financial assessments, criminal record checks, and evaluations of business performance. This ensures that companies work with suppliers who are trustworthy and have a proven track record of reliability.

- Contractor and Partner Risk Mitigation: Precisehire also assists businesses in verifying contractors and partners by conducting due diligence and risk assessments. This helps ensure that businesses only engage with partners who align with their standards for quality, reliability, and ethics.

By utilizing Precisehire’s services, companies can reduce the risk of fraud, financial instability, and operational disruptions, allowing them to build secure, long-term partnerships with their suppliers and contractors.

Data Table: Supply Chain Risk Mitigation Strategies

| Risk Mitigation Strategy | Description | Benefits |

|---|---|---|

| Risk Identification | Regularly assess supply chain risks through audits and analysis. | Helps proactively identify and address potential risks. |

| Supplier Diversification | Source materials from multiple suppliers or regions. | Reduces dependency and avoids single-point failures. |

| Technology Integration | Use AI, predictive analytics, and blockchain for monitoring risks. | Enhances real-time risk monitoring and decision-making. |

| Strong Communication & Partnerships | Build strong relationships with suppliers and logistics providers. | Ensures faster problem resolution and better cooperation. |

| Contingency Planning | Prepare for unexpected disruptions with backup plans and resources. | Minimizes downtime and financial losses during disruptions. |

By following these strategies, companies can greatly improve their ability to identify, assess, and mitigate risks in their supply chains, resulting in smoother operations and reduced vulnerability to disruptions.