Effective Supply Chain Risk Mitigation Strategies

Introduction to Supply Chain Risk and the Need for Mitigation Strategies

In today’s globalized economy, businesses rely heavily on their supply chains to deliver products and services to customers. However, supply chains are exposed to numerous risks that can disrupt operations, damage financial performance, and harm a company’s reputation. Understanding supply chain risks and having effective mitigation strategies in place is essential for businesses that want to protect their operations and ensure long-term success.

What is Supply Chain Risk?

Supply chain risk refers to any potential threat that could disrupt the flow of goods, services, or information within a company’s supply chain. These risks can arise from a variety of sources, including natural disasters, geopolitical events, supplier failures, economic shifts, and technological failures. When these risks materialize, they can lead to delays, increased costs, or even complete operational shutdowns.

Why is Mitigating Supply Chain Risk Important?

Supply chain disruptions can significantly impact a business’s ability to deliver products or services to its customers on time, leading to lost sales, customer dissatisfaction, and reputational damage. Moreover, these disruptions can have far-reaching effects, leading to financial losses, increased operational costs, and even legal and regulatory issues.

Mitigating these risks is crucial to maintaining a smooth and efficient supply chain. Risk mitigation strategies aim to identify potential vulnerabilities and address them before they cause problems. This proactive approach helps businesses reduce the likelihood of disruptions and enables them to respond quickly and effectively when issues do arise.

Types of Risks in Supply Chains

Supply chain risks can be categorized into several types, each with its own set of challenges and mitigation approaches. Let’s explore some of the most common types of risks that businesses face in their supply chains:

1. Operational Risks

Operational risks are the risks that arise from the day-to-day functioning of the supply chain. These can include disruptions in production, issues with labor, delays in transportation, or supply shortages. Operational risks can lead to delays, reduced production capacity, and increased costs.

Examples of Operational Risks:

- Manufacturing defects or quality control issues

- Labor strikes or disputes

- Disruptions in transportation or logistics

2. Financial Risks

Financial risks are associated with fluctuations in the financial stability of suppliers, cost variations, and payment issues. These risks can impact a company’s profitability and liquidity. For instance, sudden price increases from suppliers or payment delays can significantly affect the bottom line.

Examples of Financial Risks:

- Supplier bankruptcies or financial instability

- Exchange rate fluctuations

- Rising raw material costs

3. Geopolitical Risks

Geopolitical risks arise from political instability, trade barriers, or changing regulations in different regions. These risks can impact the supply of goods across borders and affect the cost and speed of operations.

Examples of Geopolitical Risks:

- Trade tariffs and sanctions

- Political instability in supplier countries

- Changes in international regulations or compliance requirements

4. Environmental Risks

Environmental risks stem from natural disasters or climate change that can disrupt supply chains. These risks can affect production sites, transportation networks, and supplier operations. With the increasing frequency of extreme weather events, businesses must prepare for potential disruptions due to environmental factors.

Examples of Environmental Risks:

- Natural disasters (earthquakes, floods, hurricanes)

- Climate change affecting raw material availability

- Supply disruptions caused by environmental regulations

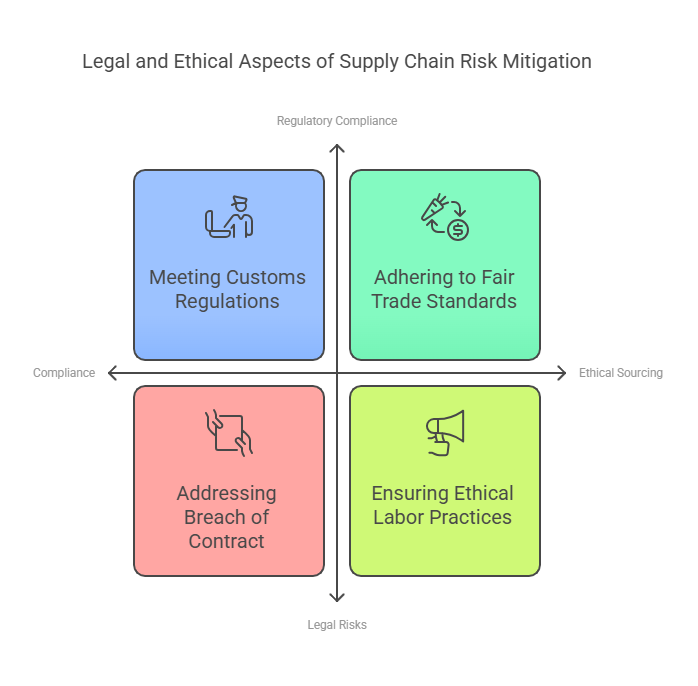

Importance of Proactive Risk Management

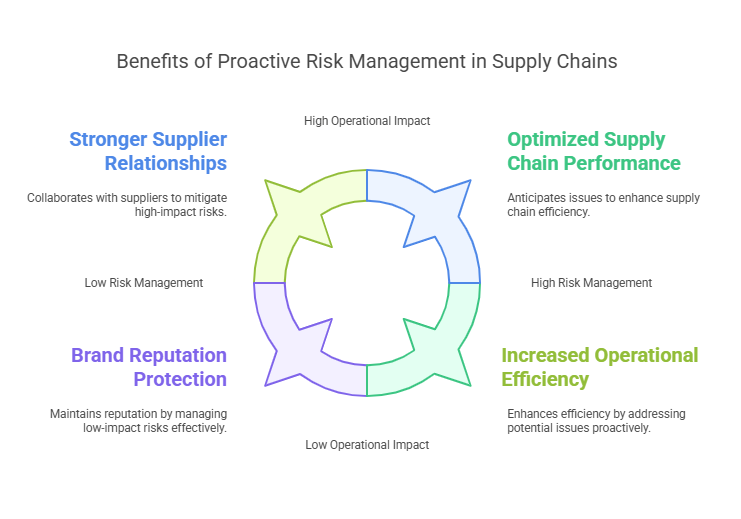

A proactive approach to risk management is essential to maintaining a resilient and responsive supply chain. By identifying potential risks early and implementing risk mitigation strategies, businesses can reduce the impact of supply chain disruptions and ensure the continuity of their operations.

Proactive risk management also helps businesses:

- Optimize supply chain performance by anticipating and addressing potential issues before they affect operations.

- Build stronger relationships with suppliers and partners by working collaboratively to manage risks.

- Protect their brand reputation by ensuring consistent delivery of high-quality products and services.

- Increase operational efficiency and reduce the costs associated with supply chain disruptions.

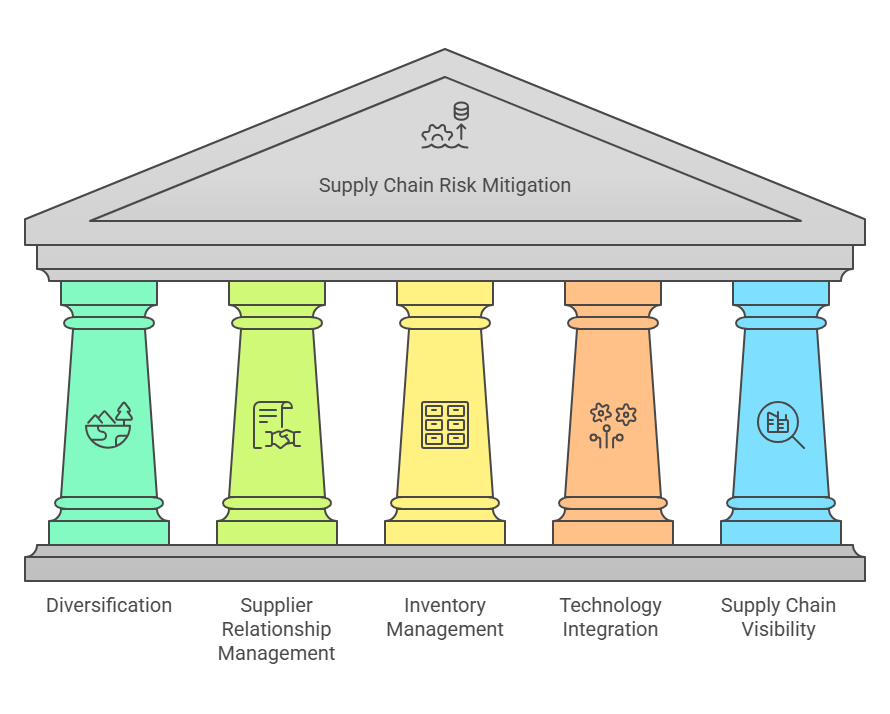

Supply Chain Risk Mitigation Strategies and Tools

To effectively manage supply chain risks, businesses must adopt a combination of strategies and tools that address various potential threats. By identifying, analyzing, and responding to risks proactively, organizations can minimize disruptions and ensure a more resilient and stable supply chain. Below are the primary strategies businesses employ to mitigate risks in their supply chains.

Key Strategies for Mitigating Supply Chain Risks

- Diversification

Diversification is one of the most common and effective strategies for mitigating supply chain risks. By avoiding dependence on a single supplier, region, or transportation route, businesses can reduce the likelihood of significant disruptions. Diversification allows companies to adapt to challenges and continue operations even if one source or route experiences a disruption.

Benefits of Diversification:

- Reduces the risk of supply chain disruptions caused by political instability, natural disasters, or supplier issues in one region.

- Increases flexibility in sourcing and logistics by offering alternative options.

- Improves business continuity, allowing the company to maintain operations in the face of localized risks.

Example: A company that sources materials from multiple countries can minimize the risk posed by geopolitical factors, such as trade tariffs or political unrest, in one country. By having multiple sources, the business can continue operations even if one supplier faces challenges.

- Supplier Relationship Management (SRM)

Supplier Relationship Management (SRM) emphasizes the importance of developing strong, long-term relationships with key suppliers. By working closely with suppliers, businesses can better understand their capabilities, risks, and challenges, ensuring more reliable service and better risk management. SRM focuses on collaboration, mutual trust, and transparency.

Benefits of SRM:

- Improved communication and transparency between businesses and suppliers, allowing risks to be identified and addressed early.

- Stronger partnerships, which can help businesses gain priority during shortages or disruptions.

- Increased trust and reliability, which encourages suppliers to collaborate on risk mitigation plans.

Example: Regular meetings, joint risk assessments, and long-term agreements with key suppliers ensure both parties are aligned on risk management practices. This collaboration can help develop contingency plans, such as alternative sourcing options or shared inventory reserves, to minimize the impact of disruptions.

- Inventory Management

Effective inventory management is essential to buffer against supply chain disruptions. By maintaining optimal stock levels, businesses can absorb short-term disruptions without facing significant impacts on production or service delivery. A robust inventory management system enables businesses to adjust quickly to unforeseen challenges and maintain operations even during supply delays.

Benefits of Effective Inventory Management:

- Prevents stockouts and keeps production lines running smoothly.

- Offers a buffer against supply disruptions, allowing businesses to continue operating until the issue is resolved.

- Helps businesses manage demand fluctuations during periods of uncertainty, such as economic downturns or natural disasters.

Example: A business might keep an extra 30 days’ worth of critical raw materials in stock to ensure production can continue if a supplier faces a shipping delay. This approach provides enough time to secure alternate suppliers or routes while avoiding production stoppages.

- Technology Integration

Technologies such as Artificial Intelligence (AI), blockchain, and predictive analytics play a significant role in mitigating supply chain risks. These tools enable businesses to gain better visibility, enhance forecasting, and improve decision-making, ultimately reducing the likelihood and impact of risks. By integrating technology into supply chain operations, businesses can better anticipate disruptions and respond more efficiently.

Benefits of Technology Integration:

- Improved forecasting and demand planning through data-driven insights, reducing uncertainty.

- Real-time visibility into the entire supply chain, allowing businesses to identify and react to disruptions as they occur.

- Enhanced data security and transparency, reducing the risk of fraud or errors.

Example: AI-powered predictive analytics can forecast demand spikes or supply shortages based on historical data and market trends. Blockchain technology, on the other hand, provides a transparent and immutable record of transactions throughout the supply chain, ensuring data integrity and reducing fraud risks.

- Supply Chain Visibility

Supply chain visibility refers to the ability to track and monitor the flow of goods and services throughout the entire supply chain in real-time. By implementing visibility tools, businesses can gain insights into potential disruptions or inefficiencies before they escalate. Having a clear view of the supply chain also enables faster decision-making and better risk management.

Benefits of Supply Chain Visibility:

- Real-time monitoring of shipments, inventory, and production schedules, allowing businesses to take proactive measures.

- Faster identification of disruptions, enabling the business to react quickly to avoid significant impacts.

- Improved collaboration with suppliers and logistics partners by sharing real-time data and insights.

Example: A company using supply chain visibility tools might track shipments and receive alerts if there’s a delay or diversion. This information allows the company to adjust its operations, whether by shifting to an alternative supplier or adjusting inventory levels, to mitigate the impact of the delay.

Data Table: Comparison of Supply Chain Risk Mitigation Strategies

| Strategy | Description | Pros | Cons |

|---|---|---|---|

| Diversification | Reduces reliance on single suppliers or regions by spreading sourcing. | Reduces single points of failure, increases flexibility. | Can lead to increased complexity and higher management costs. |

| Supplier Relationship Management (SRM) | Focuses on building strong relationships with suppliers for mutual benefit. | Improves communication and collaboration, increases reliability. | Requires time and effort to build and maintain relationships. |

| Inventory Management | Maintaining buffer stocks to absorb shocks from disruptions. | Reduces stockouts, allows continuity of operations. | High storage costs, risks of overstocking. |

| Technology Integration | Uses AI, predictive analytics, and blockchain for better decision-making. | Improves forecasting, real-time visibility, and decision-making. | High implementation costs, requires technical expertise. |

| Supply Chain Visibility | Implements real-time tracking and monitoring of the entire supply chain. | Increases transparency, helps identify disruptions early. | Initial setup and integration can be costly. |

How Precisehire Helps Mitigate HR-Related Supply Chain Risks

Human resources are an integral part of any supply chain, and the risks associated with HR management can significantly impact overall operations. Precisehire helps businesses mitigate HR-related risks through services like employee background checks and screening. By ensuring that employees possess the necessary skills and reliability, businesses can reduce the risk of employee-related disruptions, which could otherwise affect the supply chain’s stability.

Some of the key services Precisehire offers include:

- Comprehensive background checks to verify candidate qualifications, criminal history, and work history.

- Employee screening to ensure hiring decisions align with the company’s risk management strategies.

- Risk management solutions that help businesses make informed HR decisions, reducing workforce-related risks in the supply chain.

By incorporating Precisehire’s HR risk management services, companies can protect their workforce and strengthen their supply chain’s resilience.